Flat Roofing – Felt or Rubber EPDM?

If the time has come for a new flat roof, look no further than Furber Roofing Limited the flat roofing specialists. We cover Wirral, Liverpool, Ellesmere Port, Chester and North Wales.

A lot of people have asked us which the best flat roofing material is. We could cover a lot of ground here, so let’s narrow it down to the two most commonly available flat roof choices today and try to list the positives and negatives in the fairest way possible as we see them.

What is the best new flat roof covering?

Furber Roofing Limited has been fitting new flat roofs now for over almost 60years. As you can imagine, we’ve seen nearly every type of flat roof. So if you’re looking for some advice, on which is the best flat roof covering you have just found it.

How long does a flat roof last?

Most modern flat roofs have an average lifespan of 20 – 30 years, so you would probably only have to replace it two or maybe three times in your lifetime…Unless its for aesthetic reasons flat roofs are cheaper, and of course you can also have a pretty flat roof.

WHICH IS THE BEST FLAT ROOF MATERIAL – FLAT ROOFS COMPARED

Flat roof comparison, here are the most commonly used and installed flat roof systems… Torch on Felt and Rubber EPDM.

TORCH ON FELT ROOFING:

New felt roofs can unfortunately still carry a bad reputation from the older and now unused pour and roll systems of yesteryear. Large strides have been made, and continue to be made in flexibility and durability of a modern hot flame applied torch on roofing felts. Typically applied in a 3 layer system consisting of Thermovent, a 2mm underlay and a cap sheet finish of mineral felt available in a variety of colours.

• Lifespan – Furber Roofing offer a 10 year written guarantee. A well installed torch-on felt roof could well last up to 30 years if looked after and treated well.

• Cost – The cheapest option.

• Damage resistance – Foot traffic in hot weather may scuff the surface of a mineral finish; this can lead to U.V. damage by sunlight. Window cleaners also put step ladders and ladders on them in hot weather which could damage the surface.

• Repair – Easily repaired but patches on top can look messy, the plain cap sheet with solar reflective paint is the most repairable and popular in unseen and industrial settings for this reason.

• Appearance – Beauty is in the eye of the beholder, but we think a mineral finish is pretty to look at.

• Flexibility – Modern roofing felt has good expansion and contraction properties.

• Vapour transmission – Roofs are often called on to breathe. Thanks to the vapour layer a felt roof will do this. We would however personally never rely on a roof covering alone, especially if you have condensation issues. This should be dealt with in house or during roof construction.

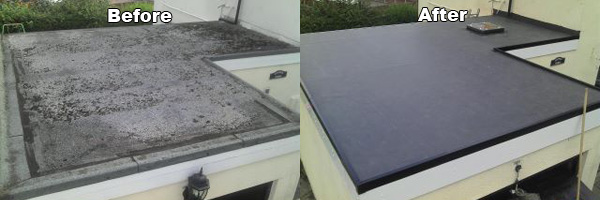

RUBBER EPDM ROOF – FIRESTONE OR SIMILAR:

These have stormed the market since being introduced a few years ago in the U.K. A rubber roof can be often installed in one complete layer without the need for joins depending on size, which is often an attractive prospect. It is also extremely light weight, elastic and tough, so it lends itself to many situations. Mostly rubber roofs are glued down to the decking (wooden substrate ) so if you had a felt roof previously the timber deck will probably need replacing. A well installed rubber roof can be a very good option.